Head Expanders & Fixtures

ETS Solutions offers Head Expanders for applications where larger vertical test mounting surfaces are required. Head Expanders are manufactured from lightweight magnesium alloy, providing high strength-to-weight ratio. A choice of less expensive aluminum alloy is also available for smaller fixtures.

The Head Expander allows multiple items to be tested at the same time, decreasing total test cycle time. Head Expanders with load support guidance allow payloads with large footprints to be safely mounted and tested on the shaker, reducing the risk of damage to the shaker suspension system.

FEATURES

Uniform surface obtained by precision machining

Magnesium composition fixture for lower total operating mass

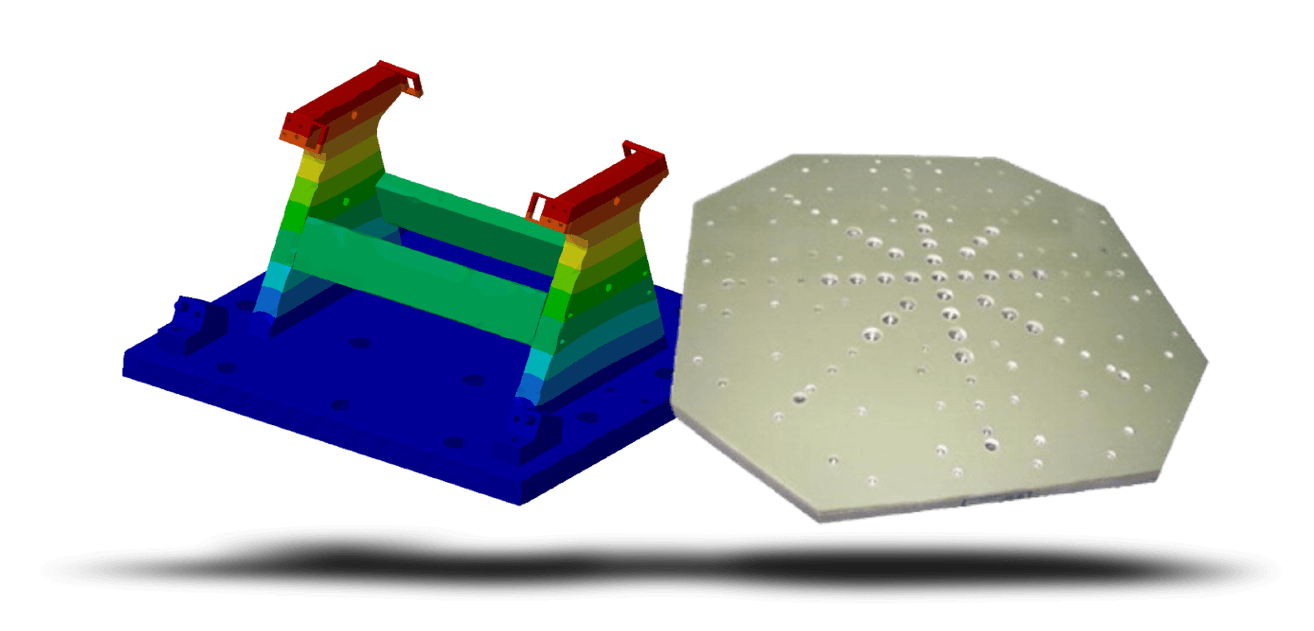

FEM designed fixtures for predictable results

Round, square and octagon shape Head Expander are available

Useful frequency up to 2,000Hz

Designed to couple with your current shaker system

Integrated easily for use with thermal chamber and with optional thermal barrier

Cost effective to increases production testing yield

High resonant frequencies available, depending on size

Choice of insert mounting hole pattern available

Special surface processing by coating with protect layer could achieve a long time operating

HEAD EXPANDER

Head Expanders are manufactured from light-weight magnesium alloys, providing high strength to weight ratio. A choice of less expensive aluminium alloys is also available for smaller fixtures without much addition to the total mass.

The Head Expander allows multiple items to be tested at the same time, decreasing total test.

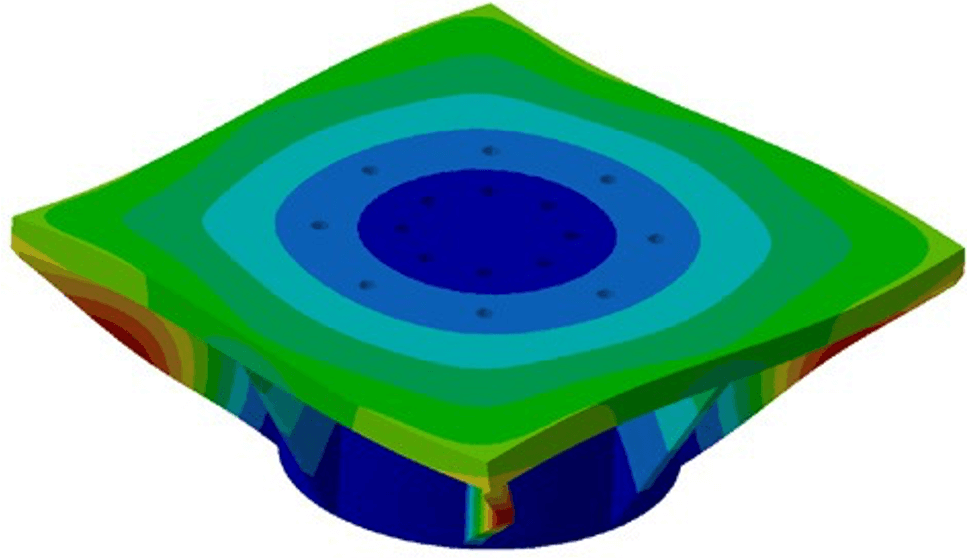

A group of experienced engineers provide a turnkey of head expander solutions by FEM design, accurately calculation, precise machining, special processing makes, flatness and parallelism working surface and insure maximum strength and penetration.

Latest software for precision calculation is incorporated into the fixture designs to produce the best results for designed fixture with an overall dynamic performance.

Guided Head Expander and Slip Table meet Customers exact testing requirements.

Special Projects

Two 20 ton (20,000 kgf) Vibration Systems, Guided Head Expander and a special Slip Table were supplied to an international railcar company for testing large and heavy test loads with a high center of gravity. Engineers at our research center in Beijing ensured the dynamic performance of the Head Expander was inline with the customers expectations using the latest FEM analysis software.

Equipment:

2 – ETS Solutions H Series Water Cooled Shakers

2 – ETS Solutions MPA Series Switching Power Amplifiers

1 – 11.5 x 9.8 ft (3.5 x 3 meter) Special T Bearing Slip Table - slip plate mass 7,500 lb (3,400 kg), static load capability 10 ton (10,000 kg)

1 - 11.5 x 9.8 ft (3.5 x 3 meter) Guided Head Expander – aluminium head expander mass 8,377 lb (3,800 kg), static load capability 8 ton (8,000 kg)

Special Customized Fuxtures

3.5 x 3m HE with 16 Ton Load Support and Guidance System.

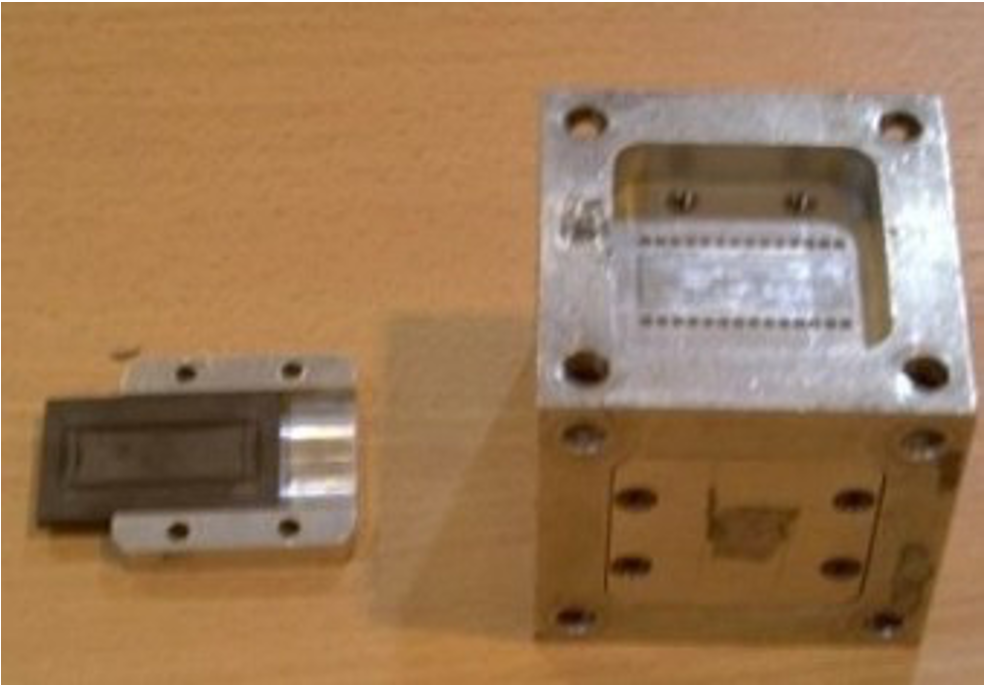

Cube Fixture for Components Testing.

Cube Fixture for Semiconductors.

Special Dual Shaker Coupling Test Jig.

Special Test Jig for Vehicle Alternator Type-2

Test Jig for Exhaust Manifold.

Test Jig for Shaft Coupling.

Test Rig for Satellite Dish.

LOAD SUPPORT SYSTEM

-

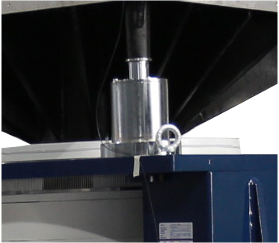

Head Expanders with load support guidance allows payloads with large foot prints to be safely mounted and tested on the shaker, reducing the risk of damage to the shaker suspension system.

The Guided Head Expanders are designed for testing of large, heavy packages to handle tough transportation and other demanding test profiles while providing additional restraints and load support. The load support system has different options to maintain different testing requirements. An ideal testing result achieved by optimized design, latest software analysis, and perfect machine.

BEARING GUIDANCE

-

Provide good constraints for cross-axial, rotation and overturning. Utilize linear bearings and number of shear mountings, which is optimized for high center- of-gravity and off-set load.

High frequency

Stable and safe

Easy to install and maintain

No damage to the system suspension system

LOAD ISOLATION SUPPORT

-

Pneumatic isolation support is supported by the air bags and bearings. Its low frequency applied option.

Economical cost

Reasonable isolator array

Restraint rotation and overturning

Easy to be installed and aligned

THERMAL BARRIER

-

G10 insulating sheet provides bolts pattern on the surface. Could be rigidly installed onto slip table for horizontal operation with chamber.

HE900RDM-480 with Thermal Barrier & Load Support for 2 Ton Payload

GUIDED LIFTING SYSTEM

-

Guided head expander fifting post for quick axial switch over.