Electric Vehicle's Battery Testing

The global market for electric vehicles has experienced a notable surge in recent years, reflecting a marked shift towards sustainable transportation solutions. Projections indicate that the momentum is set to continue, with forecasts suggesting that electric vehicles will constitute approximately 35% of all new car purchases by the year 2025. This significant rise underscores the increasing adoption of electric vehicles as a mainstream choice among consumers worldwide, signaling a pivotal juncture in the automotive industry's evolution towards more eco-friendly and energy-efficient modes of transportation.

BATTERY, as one of the most CRITICAL parts of electric vehicles, is also having a significant development period in order to fulfill the requirements of Electric Vehicle manufacturers. The testing standards and procedures are also being evaluated continuously.

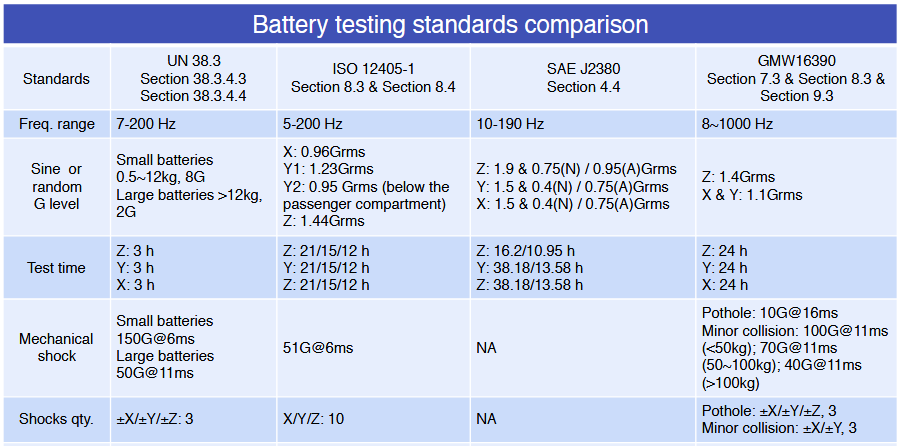

The battery needs to be subjected to vibration and shock testing to ensure the safety and robustness of the battery technology. Presently, there are three international test standards that are commonly used for Vibration and Shock Testing for Batteries. They are UN 38.3, ISO 12405-1, and SA J2380. Even though some vehicle manufacturer has their own test standards.

The ISO 12405 itself classifies the test sequences into two parts, the Battery System and the Electronic System.

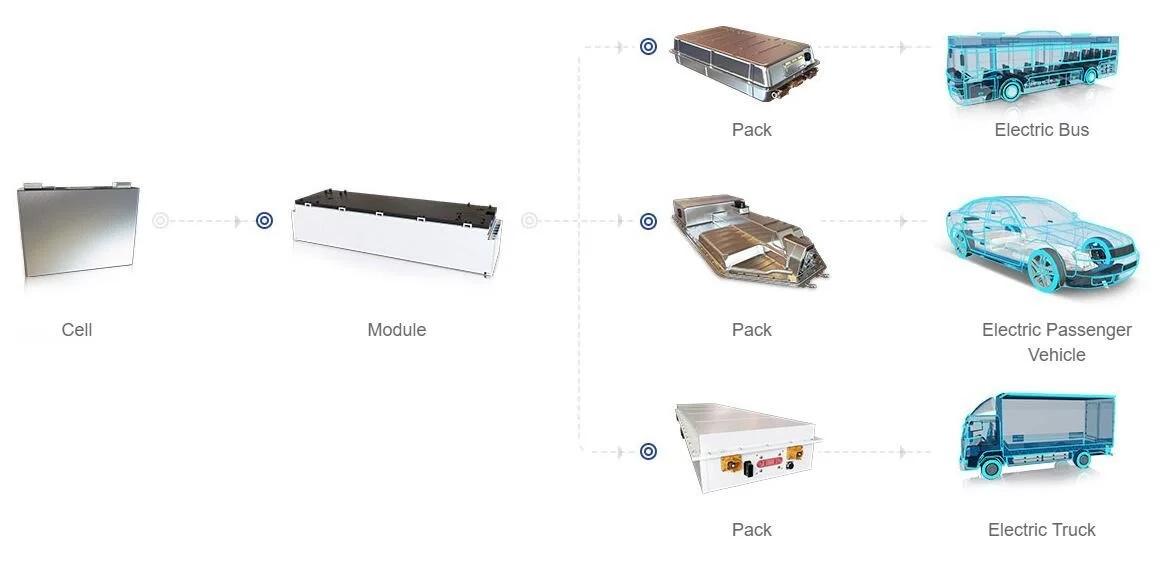

Type of Battery product system:

Cell

Module

Pack

Entire Vehicle Battery System

ETS SHAKER SERIES with IPA Amplifier technology is designed to meet the requirement of Battery vibration and shock test standards. The Vibration Controller software has also been developed to ensure the testing accuracy.

Together with long experience in Vibration Fixture design, ETS is providing one stop solution service for Vibration and Shock Testing.

Have problems with battery testing? Please do not hesitate to contact us, we are here to help you.