How to Buy and Use Your Vibration Shaker Wisely

Purchasing a vibration shaker is a serious investment—one that directly affects your product’s reliability, regulatory compliance, and market success. Whether you’re designing automotive parts, aerospace components, consumer electronics, or medical devices, understanding how to select and operate the right vibration testing equipment is crucial.

Vibration Testing for Safer Medical Devices

In the realm of healthcare, where human lives depend on technology, every component must function flawlessly. From diagnostic tools to implantable devices, the reliability of medical equipment is non-negotiable. One of the most critical yet often overlooked aspects of quality assurance in this industry is vibration testing for medical devices.

Sustainability in Vibration Testing: How to Optimize Energy Efficiency in Testing Systems

In today's world, sustainability is no longer an option—it’s a necessity. Industries across aerospace, automotive, and electronics manufacturing are increasingly prioritizing eco-friendly practices, including their testing processes.

A Deep Dive Into Vibration Test Standards Across Industries

In the world of manufacturing and engineering, ensuring product reliability and durability isn't just a competitive advantage—it’s a necessity. Vibration testing plays a critical role in meeting international compliance standards and ensuring safety across industries like aerospace, automotive, electronics, and defense.

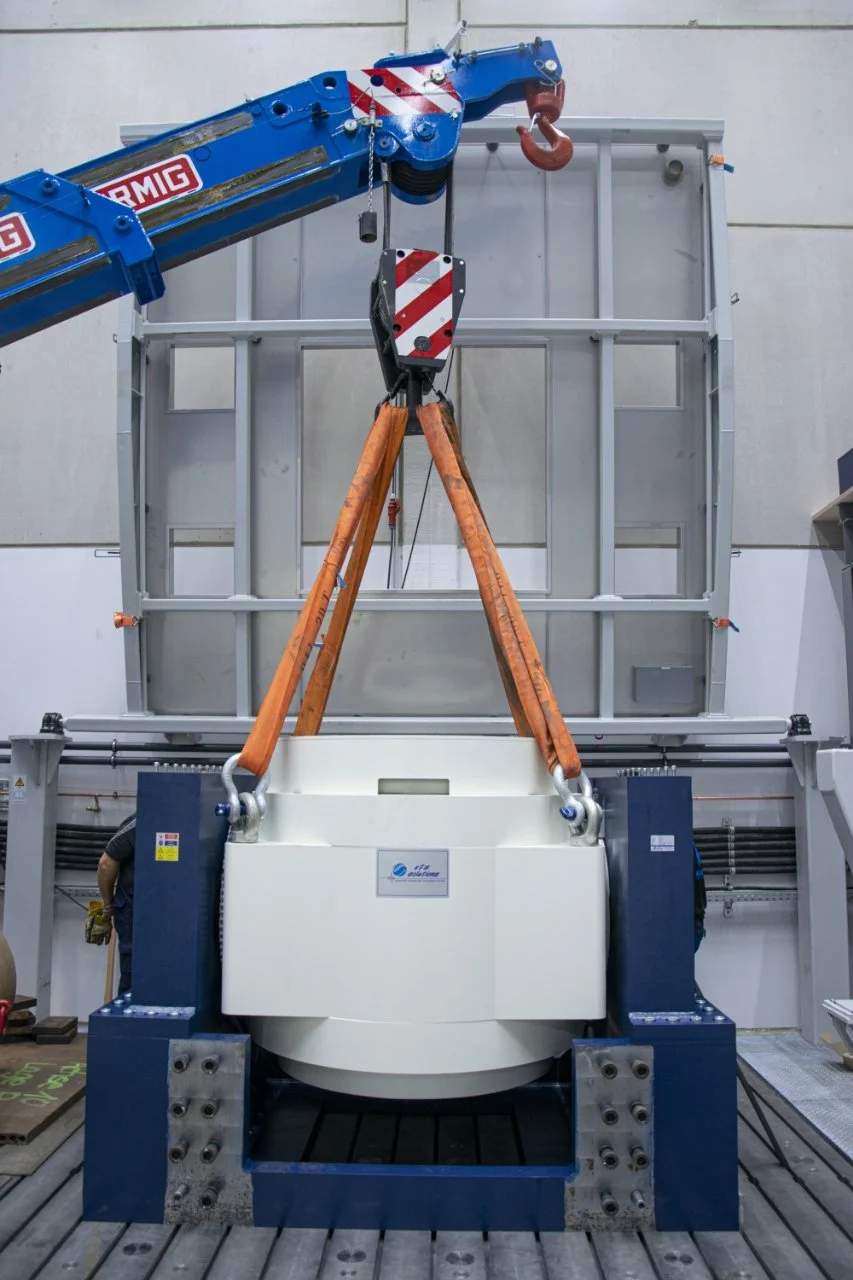

Customized Vibration Testing Solutions by ETS Solutions

In today’s rapidly evolving industries, one size doesn’t fit all—especially when it comes to vibration testing systems. Whether you're designing spacecraft components, testing automotive engines, or validating consumer electronics, your testing requirements are as unique as your products.

The Cost of Ignoring Vibration Testing in Product Design

Vibration testing, a crucial process for validating product performance under real-world conditions, is often overlooked by manufacturers attempting to cut costs or reduce development time. However, skipping vibration testing can lead to significant risks, including product failure, costly recalls, and non-compliance with safety standards.

Top 5 Innovations in Vibration Testing Systems for 2025

As industries like aerospace, automotive, and electronics continue to evolve, the demand for advanced vibration testing systems has surged. These systems ensure that products meet safety, durability, and performance standards, simulating real-world conditions. In 2025, groundbreaking innovations are shaping the future of vibration testing, offering unparalleled precision, efficiency, and sustainability.

How to Choose the Right Electrodynamic Shaker

In today’s competitive landscape, ensuring product durability and reliability is more critical than ever. Whether you’re in aerospace, automotive, or electronics, vibration testing is a vital step in product development. At the heart of this process lies the electrodynamic shaker, a cornerstone of modern vibration testing systems.

Maintenance Tips to Maximize Vibration Equipment Lifespan

Vibration testing equipment, such as vibration shaker machines and vibration test machines, plays a critical role in ensuring the reliability, durability, and safety of products across industries.

The Science Behind Frequency, Amplitude & Acceleration

Vibration testing is a cornerstone of modern product development and quality assurance, ensuring that components and products can withstand real-world conditions.

Future Trends in Vibration Testing & Innovations to Watch

In a rapidly evolving industrial landscape, the demand for robust, reliable, and high-performing products is at an all-time high. Across industries like automotive, aerospace, electronics, and defense, vibration testing is critical for ensuring that products can withstand real-world conditions.

How Vibration Testing Boosted Automotive Reliability

In the fiercely competitive automotive industry, manufacturers are under constant pressure to enhance the reliability and durability of their products.

How Vibration Testing Ensures Safety and Compliance

Products across various industries must meet strict international standards to ensure they are safe, reliable, and durable. One essential process that helps manufacturers meet these standards is vibration testing.

Optimizing Vibration Testing for Electronics

As electronics manufacturers push for innovation, ensuring product reliability has never been more crucial. Whether for smartphones, laptops, or aerospace components, vibration testing is a critical step in simulating real-world conditions to guarantee that products can withstand operational stresses.

How to Choose the Right Vibration Shaker for Your Industry

Vibration testing is critical for product development in industries like automotive, aerospace, electronics, and more. Ensuring that components and systems can withstand real-world conditions, such as shocks, vibrations, and other environmental stresses, helps guarantee product reliability and durability.

The Evolution of Vibration Testing: Past to Present

Vibration testing systems have become indispensable tools in industries ranging from automotive and aerospace to electronics and defense.

Vibration Testing Standards for Electronics Manufacturers

In the fast-evolving world of electronics manufacturing, ensuring the reliability and durability of products is paramount. From smartphones and laptops to complex industrial control systems, electronic components are expected to perform flawlessly under a wide range of conditions.

Automotive Vibration Testing Standards & Requirements

In the automotive industry, ensuring the safety, reliability, and durability of vehicles is paramount. Vibration testing plays a crucial role in achieving these goals by simulating the real-world conditions that vehicles and their components will endure throughout their lifecycle.

Understanding the Mechanics of Electrodynamic Shakers

In the world of product testing, ensuring reliability and durability is essential. Across industries such as automotive, aerospace, electronics, and defense, vibration testing plays a crucial role in verifying that products can withstand the stresses they will encounter in real-world conditions.

Vibration Testing Standards for Aerospace Manufacturers

Vibration testing requirements for an aerospace manufacturer are typically guided by various industry standards designed to ensure that components and systems can withstand the rigors of operation in the demanding aerospace environment.